mini giant excavator n220 model 124175 leaking hydrolics Learn how to solve nine common issues with mini excavators, such as hydraulic leaks, engine trouble, broken boom, and more. Find step-by-step instructions and tips for replacing seals, filters, tracks, buckets, and motors. Didcot Plant News. The latest news from the world of Didcot Plant. . A new .

0 · Troubleshooting Common Mini Excavator Issues: From Starters

1 · Troubleshooting Common Issues with Mini Excavator Final Drives

2 · 9 Most Common Problems With Mini Excavators And How To Fix

Operated Mini-Digger Hire Devon. We cover all of East Devon, Exeter & Exminster. We operate a 1.6 tonne machine with a full range of buckets and mechanical grab. Our Operated Mini-Digger .

Q: Why does my mini excavator make loud noises but fail to start? A: Loud .

skid steer insurance manitoba

Learn how to solve nine common issues with mini excavators, such as hydraulic .In this blog post, we’ll explore some of the most common issues that occur with mini excavator . Q: Why does my mini excavator make loud noises but fail to start? A: Loud noises without startup generally indicate starter motor issues. Troubleshoot the starter, checking battery charge, electrical connections, starter relay, and motor gear engagement.

Troubleshooting Common Mini Excavator Issues: From Starters

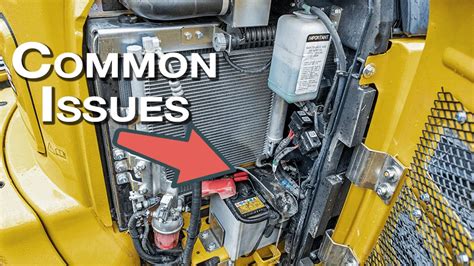

Learn how to solve nine common issues with mini excavators, such as hydraulic leaks, engine trouble, broken boom, and more. Find step-by-step instructions and tips for replacing seals, filters, tracks, buckets, and motors.In this blog post, we’ll explore some of the most common issues that occur with mini excavator final drives and provide step-by-step troubleshooting tips to help you keep your machine running smoothly. 1. Leaking Hydraulic Fluid Symptoms: Visible oil stains under the machine. Loss of hydraulic power or sluggish performance. Causes:

A hydraulic leak occurs when there is an unintended escape of hydraulic fluid from the system. These leaks are often a result of wear and tear, leading to compromised seals, damaged hoses, or loose fittings. For leak detection, a visual inspection should be the first step—which involves checking for wet spots or drips on and around the hydraulic cylinder which usually indicate a leak. In addition, using a pressure gauge to test if the cylinder is maintaining the required pressure can help confirm a leak’s presence and severity. #1. Hey, brothers. I just hit 1000 hours on my John Deere 35G and that means a bunch of maintenance items are due, including a couple of filters on the hydraulic system. By following these steps and taking into account the specific circumstances of your mini excavator's final drive leak, you can make an informed decision between repairing or replacing the affected components.

Troubleshooting Common Issues with Mini Excavator Final Drives

9 Most Common Problems With Mini Excavators And How To Fix

The hydraulic system that makes your compact equipment functional will eventually have problems, and the sooner you can fix those problems the sooner you'll be up and running again. Here are three troubleshooting tips which may seem obvious to some of you but are worth a quick review. Tip #1 - Identify What the Problem Is.

Maximize mini excavators' performance with hydraulic system maintenance tips. Learn how to inspect it and extend equipment life.

However, at times, the excavator may lose hydraulic power due to various faults in the complex hydraulic system. This article will explain why the excavator loses power when the hydraulics becomes hot.

Q: Why does my mini excavator make loud noises but fail to start? A: Loud noises without startup generally indicate starter motor issues. Troubleshoot the starter, checking battery charge, electrical connections, starter relay, and motor gear engagement. Learn how to solve nine common issues with mini excavators, such as hydraulic leaks, engine trouble, broken boom, and more. Find step-by-step instructions and tips for replacing seals, filters, tracks, buckets, and motors.In this blog post, we’ll explore some of the most common issues that occur with mini excavator final drives and provide step-by-step troubleshooting tips to help you keep your machine running smoothly. 1. Leaking Hydraulic Fluid Symptoms: Visible oil stains under the machine. Loss of hydraulic power or sluggish performance. Causes:A hydraulic leak occurs when there is an unintended escape of hydraulic fluid from the system. These leaks are often a result of wear and tear, leading to compromised seals, damaged hoses, or loose fittings.

For leak detection, a visual inspection should be the first step—which involves checking for wet spots or drips on and around the hydraulic cylinder which usually indicate a leak. In addition, using a pressure gauge to test if the cylinder is maintaining the required pressure can help confirm a leak’s presence and severity. #1. Hey, brothers. I just hit 1000 hours on my John Deere 35G and that means a bunch of maintenance items are due, including a couple of filters on the hydraulic system.

By following these steps and taking into account the specific circumstances of your mini excavator's final drive leak, you can make an informed decision between repairing or replacing the affected components. The hydraulic system that makes your compact equipment functional will eventually have problems, and the sooner you can fix those problems the sooner you'll be up and running again. Here are three troubleshooting tips which may seem obvious to some of you but are worth a quick review. Tip #1 - Identify What the Problem Is.

Maximize mini excavators' performance with hydraulic system maintenance tips. Learn how to inspect it and extend equipment life.

We provide a wide range of machinery including mini diggers, backhoe loaders, excavators and dumpers plus tools such as power tools, leaf blowers, mowers, apparel and much more. More About Us Hand picked

mini giant excavator n220 model 124175 leaking hydrolics|Troubleshooting Common Issues with Mini Excavator Final Drives